Neodymium Magnet

NdFeB Products:

Neodymium permanent magnet material available in the early 1980s, is now widely used in motor (motor), speakers (speaker), toys (toys) and some electrical appliances (electron), and other products. Components for Nd2Fe14B. Have very high magnetic properties, the largest energy product (BHmax) higher than the ferrite (Ferrite) 10 times more. Its own mechanical properties is also very good, cutting different shapes and bored. High-performance products of the highest temperature of up to 200 degrees Celsius. Because of its material content easily lead to corrosion, according to different requirements of different surface coating. (Such as plating Zn, Ni, Au, Epoxy, etc.)

Magnetic-ho, the advantage - the latest product technology:

1. We are gradually improving and advanced the implementation of the "automatic scales casting - hydrogenation, steam-ground flour - the closure of pressure - for sintering" production methods.

2. Possession of advanced processing and production lines, all kinds of machines more than 3000 units to undertake various kinds of high-volume orders.

3. can be mass-produced ultra-small and very large magnet. If Φ1 mm or Φ180 mm, and so on.

4. have the most advanced surface treatment and plating production lines, chemical plating, electroplating, plating and organic compound phosphate spraying and treatment.

5. the use of advanced production technology of hypoxia excellent corrosion-resistant magnet production and mass production of high-performance NdFeB N45 above products. Mass production can supply sufficient magnetic radiation isotropic and anisotropy NdFeB magnetic ring.

6. based on the establishment of ISO quality system, and implementing the 6 sigma quality management thinking, and optimize the production process, reducing cost of the product.

7. advanced physics and chemistry laboratory and a strong R & D team as the production of high-performance, high-quality products strong guarantee.

8. a number of senior experts in related subjects in the research and production security, well-known research institutions and start cooperation on cross-cutting.

General informatin of ndfeb magnet:

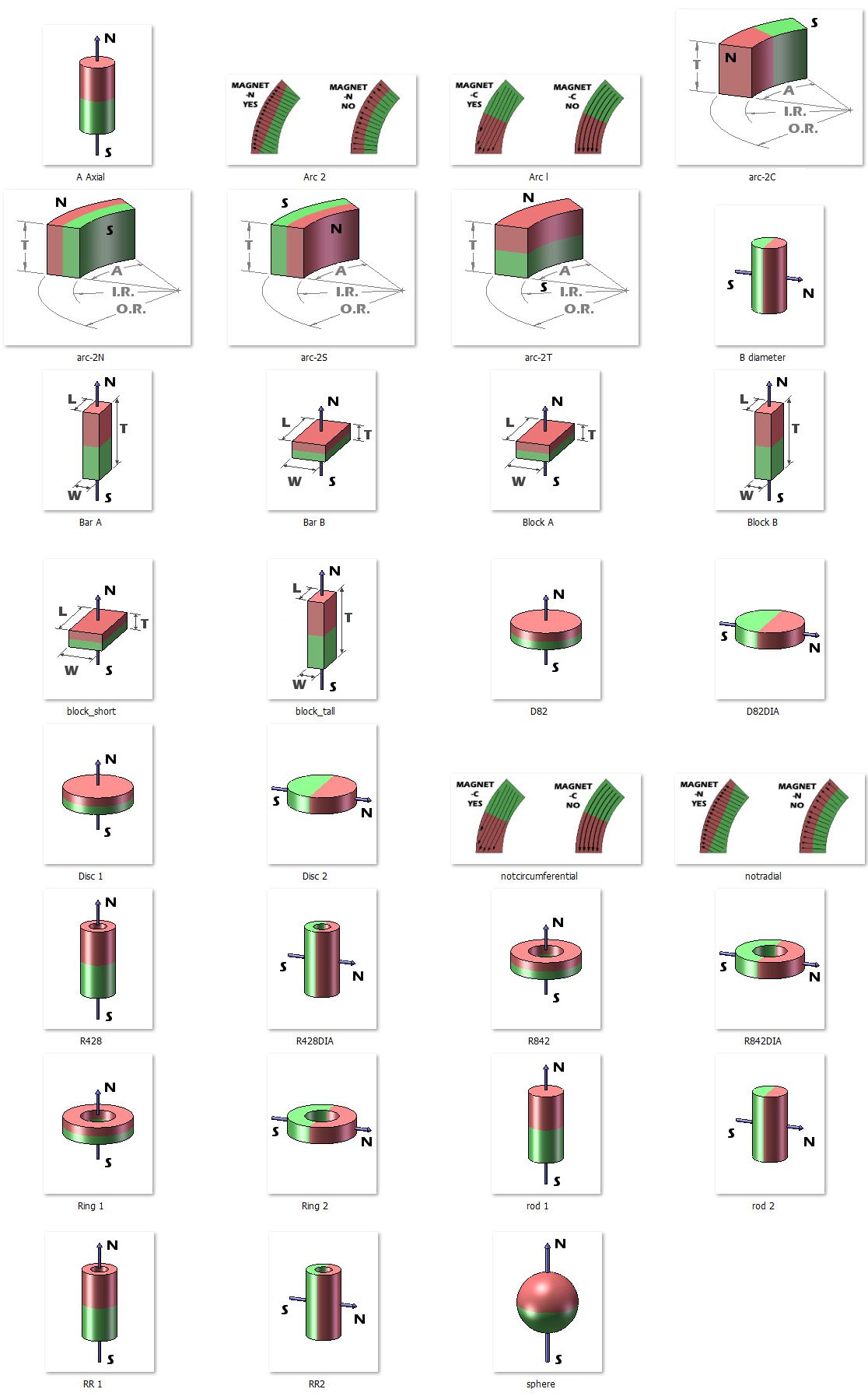

1.Shape:ring, cylinder, block, arc, ladder and any typ with hole.

2. Size limitation:

2" max in magnetized direction

5" max diameter for discs and rings

1/32" minimum on thickness

1/16" minimum diameter on outer diameter

3.Various coatings: Ni, Zn, Ag, Plastic, Phosphor, Epoxy, Au, Parylene

Grades | Remanence Br | Coercive Force Hcb | Intrinsic Coercivity Hcj | Maximum Energy Product (BH)max | Curie Temp. TC | Temp. Coefficient TW |

T | KGs | KA/m | KOe | KA/m | Koe | KJ/m3 | MGOe | ℃ | ℃ |

N35 | 1.18-1.23 | 11.8-12.3 | ≥868 | ≥10.9 | ≥955 | ≥12 | 263-287 | 33-36 | 310 | ≤80 |

N38 | 1.22-1.28 | 12.2-12.8 | ≥899 | ≥11.3 | ≥955 | ≥12 | 287-310 | 36-39 | 310 | ≤80 |

N40 | 1.26-1.31 | 12.6-13.1 | ≥923 | ≥11.6 | ≥955 | ≥12 | 302-326 | 38-41 | 310 | ≤80 |

N42 | 1.28-1.34 | 12.8-13.4 | ≥923 | ≥11.6 | ≥955 | ≥12 | 318-342 | 40-43 | 310 | ≤80 |

N45 | 1.33-1.38 | 13.3-13.8 | ≥923 | ≥11.6 | ≥955 | ≥12 | 342-366 | 43-46 | 310 | ≤80 |

N48 | 1.38-1.42 | 13.8-14.2 | ≥923 | ≥11.6 | ≥955 | ≥12 | 358-390 | 45-48 | 310 | ≤80 |

N50 | 1.40-1.45 | 14.0-14.5 | ≥836 | ≥10.5 | ≥876 | ≥11 | 382-406 | 48-51 | 310 | ≤80 |

N52 | 1.43-1.48 | 14.3-14.8 | ≥796 | ≥10.0 | ≥876 | ≥11 | 398-422 | 50-53 | 310 | ≤80 |

N35M | 1.17-1.22 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1114 | ≥14 | 263-287 | 33-36 | 320 | ≤100 |

N38M | 1.22-1.25 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1114 | ≥14 | 287-310 | 36-39 | 320 | ≤100 |

N40M | 1.25-1.28 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 302-326 | 38-41 | 320 | ≤100 |

N42M | 1.28-1.32 | 12.8-13.2 | ≥955 | ≥12.0 | ≥1114 | ≥14 | 318-342 | 40-43 | 320 | ≤100 |

N45M | 1.32-1.38 | 13.2-13.8 | ≥995 | ≥12.5 | ≥1114 | ≥14 | 342-366 | 43-46 | 320 | ≤100 |

N48M | 1.36-1.43 | 13.6-14.3 | ≥1027 | ≥12.9 | ≥1114 | ≥14 | 366-390 | 46-49 | 320 | ≤100 |

N50M | 1.40-1.45 | 14.0-14.5 | ≥1033 | ≥13.0 | ≥1114 | ≥14 | 382-406 | 48-51 | 320 | ≤100 |

N33H | 1.14-1.19 | 11.4-11.9 | ≥836 | ≥10.5 | ≥1353 | ≥17 | 247-270 | 31-34 | 330 | ≤120 |

N35H | 1.17-1.22 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1353 | ≥17 | 263-287 | 33-36 | 330 | ≤120 |

N38H | 1.22-1.25 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1353 | ≥17 | 287-310 | 36-39 | 330 | ≤120 |

N40H | 1.25-1.28 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1353 | ≥17 | 302-326 | 38-41 | 330 | ≤120 |

N42H | 1.28-1.32 | 12.8-13.2 | ≥955 | ≥12.0 | ≥1353 | ≥17 | 318-342 | 40-43 | 330 | ≤120 |

N45H | 1.30-1.36 | 13.0-13.6 | ≥963 | ≥12.1 | ≥1353 | ≥17 | 326-358 | 43-46 | 330 | ≤120 |

N48H | 1.37-1.43 | 13.7-14.3 | ≥995 | ≥12.5 | ≥1353 | ≥17 | 366-390 | 46-49 | 330 | ≤120 |

N30SH | 1.08-1.13 | 10.8-11.3 | ≥810 | ≥10.2 | ≥1592 | ≥20 | 223-247 | 28-31 | 340 | ≤150 |

N33SH | 1.13-1.17 | 11.3-11.7 | ≥844 | ≥10.6 | ≥1592 | ≥20 | 247-271 | 31-34 | 340 | ≤150 |

N35SH | 1.17-1.22 | 11.7-12.2 | ≥876 | ≥11.0 | ≥1592 | ≥20 | 263-287 | 33-36 | 340 | ≤150 |

N38SH | 1.22-1.25 | 12.2-12.5 | ≥907 | ≥11.4 | ≥1592 | ≥20 | 287-310 | 36-39 | 340 | ≤150 |

N40SH | 1.25-1.28 | 12.5-12.8 | ≥939 | ≥11.8 | ≥1592 | ≥20 | 302-326 | 38-41 | 340 | ≤150 |

N42SH | 1.28-1.32 | 12.8-13.2 | ≥987 | ≥12.4 | ≥1592 | ≥20 | 318-342 | 40-43 | 340 | ≤150 |

N45SH | 1.32-1.38 | 13.2-13.8 | ≥1003 | ≥12.6 | ≥1592 | ≥20 | 342-366 | 43-46 | 340 | ≤150 |

N28UH | 1.02-1.08 | 10.2-10.8 | ≥764 | ≥9.60 | ≥1990 | ≥25 | 207-231 | 26-29 | 350 | ≤180 |

N30UH | 1.08-1.13 | 10.8-11.3 | ≥812 | ≥10.2 | ≥1990 | ≥25 | 223-247 | 28-31 | 350 | ≤180 |

N33UH | 1.13-1.17 | 11.3-11.7 | ≥852 | ≥10.7 | ≥1990 | ≥25 | 247-271 | 31-34 | 350 | ≤180 |

N35UH | 1.18-1.22 | 11.8-12.2 | ≥860 | ≥10.8 | ≥1990 | ≥25 | 263-287 | 33-36 | 350 | ≤180 |

N38UH | 1.22-1.25 | 12.2-12.5 | ≥876 | ≥11.0 | ≥1990 | ≥25 | 287-310 | 36-39 | 350 | ≤180 |

N40UH | 1.25-1.28 | 12.5-12.8 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 302-326 | 38-41 | 350 | ≤180 |

N28EH | 1.04-1.09 | 10.4-10.9 | ≥780 | ≥9.80 | ≥2388 | ≥30 | 207-231 | 26-29 | 380 | ≤200 |

N30EH | 1.08-1.13 | 10.8-11.3 | ≥812 | ≥10.2 | ≥2388 | ≥30 | 223-247 | 28-31 | 380 | ≤200 |

N33EH | 1.13-1.17 | 11.3-11.7 | ≥836 | ≥10.5 | ≥2388 | ≥30 | 247-271 | 31-34 | 380 | ≤200 |

N35EH | 1.17-1.22 | 11.7-12.2 | ≥876 | ≥11.0 | ≥2388 | ≥30 | 263-287 | 33-36 | 380 | ≤200 |

N38EH | 1.22-1.29 | 12.2-12.9 | ≥915 | ≥11.5 | ≥2388 | ≥30 | 287-318 | 36-40 | 380 | ≤200 |

N30AH | 1.08-1.15 | 10.8-11.5 | ≥804 | ≥10.1 | ≥2786 | ≥35 | 223-255 | 28-32 | 380 | ≤230 |

N33AH | 1.14-1.21 | 11.4-12.1 | ≥852 | ≥10.7 | ≥2786 | ≥35 | 247-279 | 31-35 | 380 | ≤230 |

Zinc-coating | Nickel-coating | Nickel-copper-Nickel | Aurum-coating | Copper-coating | Epoxy | Phosphatsing | Parylene | others |

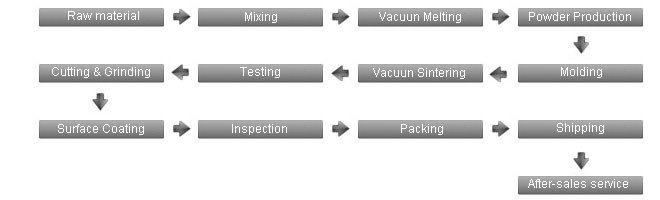

Production Chart of Sintered NdFeB

Raw material →Mixing Vacuum → Melting Powder →Production →Cutting and Grinding →Testing →Vacuum Sintering →Molding →Surface Coating →Inspection →Packing →Shipping →After-sales Service

Surface

Name | White Zinc | Colour Zinc | Nickel | Electroless

Nickel | NiCuNi | NiSn | Epoxy | Phosphating | NiAu |

Coating Thickness

(μm) | 8-15 | 10-15 | 20-30 | 20-30 | 15-30 | 20-30 | 10-30 | 1-3 | 10-20 |

Color | Blue and white | Multicolor | Silver | Silver | Silver | Silver | Black | Black | Gold |

PCT | 3 | 3 | 1 | 1 | 2 | 2 | 2 | 3 | 2 |

Humidity Test | 3 | 3 | 1 | 1 | 1 | 1 | 1 | 2 | 2 |

Salt Spray Test | 3 | 2 | 3 | 1 | 2 | 2 | 1 | 3 | 2 |

Collision Test | 2 | 2 | 1 | 1 | 1 | 1 | 1 | 3 | 1 |

General Information

Neodymium permanent magnet material available in the early 1980s, is now widely used in motor (motor), speakers (speaker), toys (toys) and some electrical appliances (electron), and other products. Components for Nd2Fe14B. Have very high magnetic properties, the largest energy product (BHmax) higher than the ferrite 10 times more. Its own mechanical properties is also very good, cutting different shapes and bored. High-performance products of the highest temperature of up to 200 degrees Celsius. Because of its material content easily lead to corrosion, according to different requirements of different surface coating. (Such as plating Zn, Ni, Au, Epoxy, etc.)

Third-generation rare earth permanent magnet of Neodymium magnets(NdFeB) is a contemporary of the strongest magnets in the permanent magnet, it is not only a high residual magnetism, high coercivity, high-energy product, such as high cost performance characteristics, and easy processing into the Sizes, it exert very high forces and can attract each other through large distances making them very popular. It iis now widely used in aviation, aerospace, electronics, electro-acoustic, mechanical and electrical, instruments, meters, antenna, medical technology and other devices needed Wing magnetic field equipment, especially for developing high-performance, small size, light And updating of the various products.

Advantages of our Neodymium Magnet:

1. We are gradually improving and advanced the implementation of the "automatic scales casting - hydrogenation, steam-ground flour - the closure of pressure - for sintering" production methods.

2. Possession of advanced processing and production lines, all kinds of machines more than 3000 units to undertake various kinds of high-volume orders.

3. can be mass-produced ultra-small and very large magnet. If Φ1 mm or Φ180 mm, and so on.

4. have the most advanced surface treatment and plating production lines, chemical plating, electroplating, plating and organic compound phosphate spraying and treatment.

5. the use of advanced production technology of hypoxia excellent corrosion-resistant magnet production and mass production of high-performance NdFeB N45 above products. Mass production can supply sufficient magnetic radiation isotropic and anisotropy NdFeB magnetic ring.

6. based on the establishment of ISO quality system, and implementing the 6 sigma quality management thinking, and optimize the production process, reducing cost of the product.

7. advanced physics and chemistry laboratory and a strong R & D team as the production of high-performance, high-quality products strong guarantee.

8. a number of senior experts in related subjects in the research and production security, well-known research institutions and start cooperation on cross-cutting.

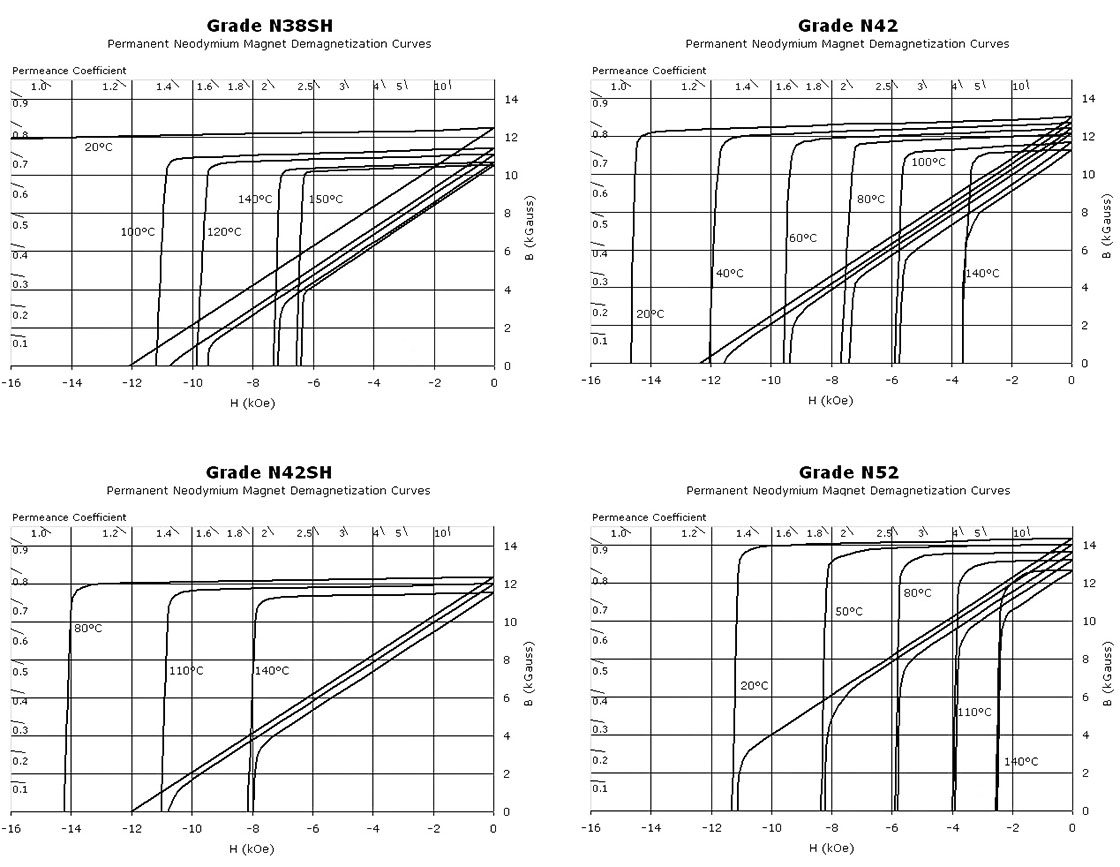

Magnetic characteristics:

Grades | Remanence Br | Coercive Force Hcb | Intrinsic Coercivity Hcj | Maximum Energy Product (BH)max | Curie Temp. TC | Temp. Coefficient TW |

T | KGs | KA/m | KOe | KA/m | Koe | KJ/m3 | MGOe | ℃ | ℃ |

N35 | 1.18-1.23 | 11.8-12.3 | ≥868 | ≥10.9 | ≥955 | ≥12 | 263-287 | 33-36 | 310 | ≤80 |

N38 | 1.22-1.28 | 12.2-12.8 | ≥899 | ≥11.3 | ≥955 | ≥12 | 287-310 | 36-39 | 310 | ≤80 |

N40 | 1.26-1.31 | 12.6-13.1 | ≥923 | ≥11.6 | ≥955 | ≥12 | 302-326 | 38-41 | 310 | ≤80 |

N42 | 1.28-1.34 | 12.8-13.4 | ≥923 | ≥11.6 | ≥955 | ≥12 | 318-342 | 40-43 | 310 | ≤80 |

N45 | 1.33-1.38 | 13.3-13.8 | ≥923 | ≥11.6 | ≥955 | ≥12 | 342-366 | 43-46 | 310 | ≤80 |

N48 | 1.38-1.42 | 13.8-14.2 | ≥923 | ≥11.6 | ≥955 | ≥12 | 358-390 | 45-48 | 310 | ≤80 |

N50 | 1.40-1.45 | 14.0-14.5 | ≥836 | ≥10.5 | ≥876 | ≥11 | 382-406 | 48-51 | 310 | ≤80 |

N52 | 1.43-1.48 | 14.3-14.8 | ≥796 | ≥10.0 | ≥876 | ≥11 | 398-422 | 50-53 | 310 | ≤80 |

N35M | 1.17-1.22 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1114 | ≥14 | 263-287 | 33-36 | 320 | ≤100 |

N38M | 1.22-1.25 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1114 | ≥14 | 287-310 | 36-39 | 320 | ≤100 |

N40M | 1.25-1.28 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 302-326 | 38-41 | 320 | ≤100 |

N42M | 1.28-1.32 | 12.8-13.2 | ≥955 | ≥12.0 | ≥1114 | ≥14 | 318-342 | 40-43 | 320 | ≤100 |

N45M | 1.32-1.38 | 13.2-13.8 | ≥995 | ≥12.5 | ≥1114 | ≥14 | 342-366 | 43-46 | 320 | ≤100 |

N48M | 1.36-1.43 | 13.6-14.3 | ≥1027 | ≥12.9 | ≥1114 | ≥14 | 366-390 | 46-49 | 320 | ≤100 |

N50M | 1.40-1.45 | 14.0-14.5 | ≥1033 | ≥13.0 | ≥1114 | ≥14 | 382-406 | 48-51 | 320 | ≤100 |

N33H | 1.14-1.19 | 11.4-11.9 | ≥836 | ≥10.5 | ≥1353 | ≥17 | 247-270 | 31-34 | 330 | ≤120 |

N35H | 1.17-1.22 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1353 | ≥17 | 263-287 | 33-36 | 330 | ≤120 |

N38H | 1.22-1.25 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1353 | ≥17 | 287-310 | 36-39 | 330 | ≤120 |

N40H | 1.25-1.28 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1353 | ≥17 | 302-326 | 38-41 | 330 | ≤120 |

N42H | 1.28-1.32 | 12.8-13.2 | ≥955 | ≥12.0 | ≥1353 | ≥17 | 318-342 | 40-43 | 330 | ≤120 |

N45H | 1.30-1.36 | 13.0-13.6 | ≥963 | ≥12.1 | ≥1353 | ≥17 | 326-358 | 43-46 | 330 | ≤120 |

N48H | 1.37-1.43 | 13.7-14.3 | ≥995 | ≥12.5 | ≥1353 | ≥17 | 366-390 | 46-49 | 330 | ≤120 |

N30SH | 1.08-1.13 | 10.8-11.3 | ≥810 | ≥10.2 | ≥1592 | ≥20 | 223-247 | 28-31 | 340 | ≤150 |

N33SH | 1.13-1.17 | 11.3-11.7 | ≥844 | ≥10.6 | ≥1592 | ≥20 | 247-271 | 31-34 | 340 | ≤150 |

N35SH | 1.17-1.22 | 11.7-12.2 | ≥876 | ≥11.0 | ≥1592 | ≥20 | 263-287 | 33-36 | 340 | ≤150 |

N38SH | 1.22-1.25 | 12.2-12.5 | ≥907 | ≥11.4 | ≥1592 | ≥20 | 287-310 | 36-39 | 340 | ≤150 |

N40SH | 1.25-1.28 | 12.5-12.8 | ≥939 | ≥11.8 | ≥1592 | ≥20 | 302-326 | 38-41 | 340 | ≤150 |

N42SH | 1.28-1.32 | 12.8-13.2 | ≥987 | ≥12.4 | ≥1592 | ≥20 | 318-342 | 40-43 | 340 | ≤150 |

N45SH | 1.32-1.38 | 13.2-13.8 | ≥1003 | ≥12.6 | ≥1592 | ≥20 | 342-366 | 43-46 | 340 | ≤150 |

N28UH | 1.02-1.08 | 10.2-10.8 | ≥764 | ≥9.60 | ≥1990 | ≥25 | 207-231 | 26-29 | 350 | ≤180 |

N30UH | 1.08-1.13 | 10.8-11.3 | ≥812 | ≥10.2 | ≥1990 | ≥25 | 223-247 | 28-31 | 350 | ≤180 |

N33UH | 1.13-1.17 | 11.3-11.7 | ≥852 | ≥10.7 | ≥1990 | ≥25 | 247-271 | 31-34 | 350 | ≤180 |

N35UH | 1.18-1.22 | 11.8-12.2 | ≥860 | ≥10.8 | ≥1990 | ≥25 | 263-287 | 33-36 | 350 | ≤180 |

N38UH | 1.22-1.25 | 12.2-12.5 | ≥876 | ≥11.0 | ≥1990 | ≥25 | 287-310 | 36-39 | 350 | ≤180 |

N40UH | 1.25-1.28 | 12.5-12.8 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 302-326 | 38-41 | 350 | ≤180 |

N28EH | 1.04-1.09 | 10.4-10.9 | ≥780 | ≥9.80 | ≥2388 | ≥30 | 207-231 | 26-29 | 380 | ≤200 |

N30EH | 1.08-1.13 | 10.8-11.3 | ≥812 | ≥10.2 | ≥2388 | ≥30 | 223-247 | 28-31 | 380 | ≤200 |

N33EH | 1.13-1.17 | 11.3-11.7 | ≥836 | ≥10.5 | ≥2388 | ≥30 | 247-271 | 31-34 | 380 | ≤200 |

N35EH | 1.17-1.22 | 11.7-12.2 | ≥876 | ≥11.0 | ≥2388 | ≥30 | 263-287 | 33-36 | 380 | ≤200 |

N38EH | 1.22-1.29 | 12.2-12.9 | ≥915 | ≥11.5 | ≥2388 | ≥30 | 287-318 | 36-40 | 380 | ≤200 |

N30AH | 1.08-1.15 | 10.8-11.5 | ≥804 | ≥10.1 | ≥2786 | ≥35 | 223-255 | 28-32 | 380 | ≤230 |

N33AH | 1.14-1.21 | 11.4-12.1 | ≥852 | ≥10.7 | ≥2786 | ≥35 | 247-279 | 31-35 | 380 | ≤230 |

Production Chart of Sintered NdFeB:

Raw material →Mixing Vacuum → Melting Powder →Production →Cutting and Grinding →Testing →Vacuum Sintering →Molding →Surface Coating →Inspection →Packing →Shipping →After-sales Service

Surface Coating:

Name | White Zinc | Colour Zinc | Nickel | ElectrolessNickel | NiCuNi | NiSn | Epoxy | Phosphating | NiAu |

Coating Thickness(μm) | 8-15 | 10-15 | 20-30 | 20-30 | 15-30 | 20-30 | 10-30 | 1-3 | 10-20 |

Color | Blue and white | Multicolor | Silver | Silver | Silver | Silver | Black | Black | Gold |

PCT | 3 | 3 | 1 | 1 | 2 | 2 | 2 | 3 | 2 |

Humidity Test | 3 | 3 | 1 | 1 | 1 | 1 | 1 | 2 | 2 |

Salt Spray Test | 3 | 2 | 3 | 1 | 2 | 2 | 1 | 3 | 2 |

Collision Test | 2 | 2 | 1 | 1 | 1 | 1 | 1 | 3 | 1 |