General Information

Ferrite magnets are sintered permanent magnets composed of Barium or Strontium Ferrite. This class of magnets, aside from good resistance to demagnetization, has the popular advantage of low cost.

Ferrite magnets are very hard and brittle, and require specialized machining techniques. Moreover, they should be machined in an unmagnetized state. We are equipped to machine these materials to specifications.

Anisotropic grades are oriented in the manufacturing direction, and must be magnetized in the direction of orientation. Isotropic grades are not oriented and can be magnetized in any direction, although some degree of greater magnetic strength will be found in the pressing dimension, usually the shortest dimension.

Due to their low cost, Ferrite magnets enjoy a very wide range of applications, from motors and loudspeakers to toys and crafts, and are the most widely used permanent magnets today.

Hard Ferrite is SrO or BaO and Fe2O3 for raw materials, through the method of ceramic made of, I Permanent Secretary for ferrite mainly Y10T (isotropic), (different side of) Y20, Y25, Y30,

Y30BH, Y35 Grade 6, and other products, product specifications are circular, cylindrical, square, trapezoidal, tile.

Ferrite is the most extensive application of a permanent magnet materials to manufacture powder metallurgy, materials can be divided into barium (Ba) and strontium material (Sr) are divided into two categories anisotropy and isotropic , Is not difficult to corrosion Demagnetization a permanent magnet material, the maximum temperature up to 250 degrees Celsius, more hard and brittle, can be used diamond cutting tools such as sand, with just alloy forming a mold for processing. A large number of such products used in permanent magnet motor (Motor) and speakers (Speaker), and other fields.

1. country rich in natural resources advantages, more than 10 years of production experience.

2. exclusive domestic product produces ultra-high thickness. (25-40 mm).

3. can produce all kinds of special-shaped products, such as drilling ring, the oval-shaped hole, horseshoe, and so on.

4. effective cost control so that we can have a considerable price advantage.

5. advanced milling equipment and unique milling process to ensure that silt uniform consistency of powder material.

6. introduction of a number of magnetic tile production equipment, and imports of South Korean high-performance powder to enhance the performance of stability.

7. the international advanced electric furnace sintering equipment, ensure the formation process of sintering temperature consistency.

8. powerful scale of production, to ensure a stable delivery.

Magnet character:

1,SJ/T 10410-93 Standard;

2,MMPA (0100-87) standard;

3,Physical and reference technical

characteristics of permanent ferrite materials;

1,SJ/T 10410-93 Standard

Material | Br | HcB | (BH)max | |||

mT | KG | KA/m | KOe | Kj/m3 | MGOe | |

Y8T | 200~235 | 2.0~2.35 | 125~160 | 1.57-2.01 | 6.5~9.5 | 0.8-1.2 |

Y20 | 320~380 | 3.2~3.8 | 135-190 | 1.70-2.38 | 18.0-22.0 | 2.3-2.8 |

Y22H | 310-360 | 3.1~3.6 | 220-250 | 2.77-3.14 | 20.0-24.0 | 2.5-3.0 |

Y23 | 320-370 | 3.2~3.7 | 170-190 | 2.14-2.38 | 20.0-25.5 | 2.5-3.2 |

Y25 | 360~400 | 3.6~4.0 | 135~170 | 1.70-2.14 | 22.5~28.0 | 2.8-3.5 |

Y26H | 360~390 | 3.6~3.9 | 220~250 | 2.77-3.14 | 23.0~28.0 | 2.9-3.5 |

Y27H | 370~400 | 3.7~4.0 | 205~250 | 2.58-3.14 | 25.0~29.5 | 3.1-3.7 |

Y28 | 370~400 | 3.7-4.0 | 175~210 | 2.20-2.64 | 26.0~30.0 | 3.3-3.8 |

Y30H~1 | 380~400 | 3.8-4.0 | 230~275 | 2.89-3.46 | 27.0~32.0 | 3.4-4.1 |

Y30H~2 | 395~415 | 3.95-4.15 | 275~300 | 3.46-3.77 | 28.5~32.5 | 3.5-4.0 |

Y32 | 400~420 | 4.0-4.2 | 160~190 | 2.01-2.38 | 30.0~33.5 | 3.8-4.2 |

Y33 | 410~430 | 4.1-4.3 | 220~250 | 2.77-3.14 | 31.5~35.0 | 4.0-4.4 |

2,MMPA (0100-87) standard

Material | Br | HcB | HcJ | (BH)max | ||||

| mT | KG | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe |

C1 | 230 | 2.3 | 148 | 1.86 | 258 | 3.5 | 8.36 | 1.05 |

Note:1mT=10Gs 1KA/m=4лOe 1KJ/m3=4л×10MGOe

3,Physical and reference technical

characteristics of permanent ferrite materials

Parameter | Mark | Unit | Value |

Recoil permeability | μ rec | Gs/Oe | 1.05-1.3 |

Curie temperature | Tc | ℃ | 450 |

The coefficient of demagnetization to temperature | α (Br) | ℃-1 | -0.2%(0-100℃) |

The coefficient of magnetization coercive force to temperature | α (Hc) | ℃-1 | 0.2%-0.5%(0-100℃) |

Density | d | g/cm3 | 4.7-5.0 |

Resistivity | ρ | Ω,cm |

|

The coefficient of linear expansion | α | ℃-1 | 7-15×10-6 |

Hardness | HV | - | 480-580 |

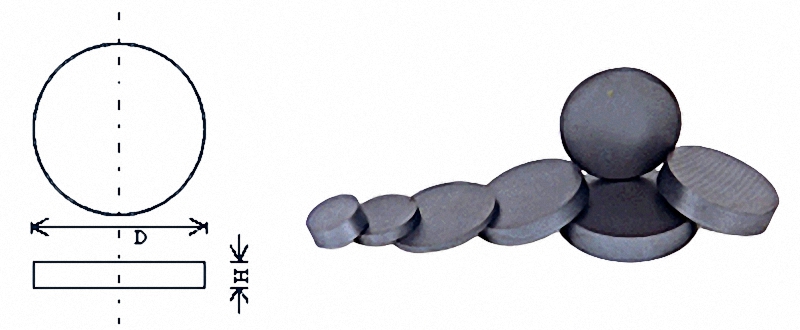

Disc shape magnets

Disc Shape Size (mm) D×H

(The dimension than the catalog stated will be supplied on request)

Ф5×1.1~15 | Ф18×2~10 | Ф36×3~12 |